Infrastructure

Factory Tour

InBlue takes pride in its manufacturing facility as we are one of the few with a dedicated local manufacturing resource. We have a complete in-house process for manufacturing uniforms and function in a 23980 sq feet area. Our manufacturing unit is equipped with modern manufacturing facilities and state-of-the-art machines, for every activity, from stitching to finishing. We have a team of 100 well trained production staff which consists of highly experienced production managers, cutting masters, linemen, machine operators and the like. All our machines are Japanese make, be it stitching machines or embroidery and printing machines. They render quality work and help us ensure that we are able to deliver what we promise.

The facility is divided into various sections with teams and their heads practicing efficient production plans to maintain high levels of effectiveness.

- The cutting section is supervised by experienced cutting masters and shapers, who know the skill of cutting. Portable and fixed cutting machines are used in cutting of fabric.

- Stitching unit is supervised by our experienced Production Manager with his well qualified and experienced lineman who strives to fulfill top class stitching parameters required by customers with various machines like flat lock and over lock machines, lock stitch machine, button hole and button stitch machine etc.

- At garment finishing stage it is ensured that each and every item has gone through rigorous inspection and is 100% defect free before packing. Latest garment pressing equipment is used including Vacuum Press tables, Thread sucking machine, stain removing machine, Electric Steam Generator for ironing, heater less stream Irons etc.

- A separate quality control department is there with highly skilled and motivated staff. Quality control policy should cover manufacturing process along-with safe handling and delivery of products, well-defined procedures for storing and packing of finished products.

- We have a separate sampling section where innovative and highly skilled designers prepare sample uniforms, according to the needs of the client.

MACHINES

Our factory has state of the art machinery which helps us reach perfection while carefully crafting every garment. The machines that we use come from leading global manufacturers, and we source the best from the best manufacturers resulting in a combination of Japanese, German and Chinese brands of machinery which work in sync to meet our quality standards.

Cutting Machine

Pressing Machine

Stitching Machine

Automatic Collar Machine

Overlock Machine

Automatic Placket Machine

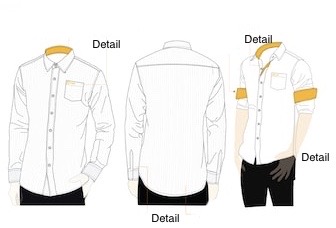

CUSTOMIZED DESIGNS

At INBLUE, we make it easy to design your own customised uniforms using our services. Whether you are looking to create unique shirts, t-shirts, hoodies, or business suits for your business or high visibility coveralls, jackets or pants for your company, we’ve got you covered. Our design consultants understand your brand image and accordingly suggest designs, styles and colours best suited for your employees.

WAREHOUSING FACILITY

At INBLUE, we make it easy to design your own customised uniforms using our services. Whether you are looking to create unique shirts, t-shirts, hoodies, or business suits for your business or high visibility coveralls, jackets or pants for your company, we’ve got you covered. Our design consultants understand your brand image and accordingly suggest designs, styles and colours best suited for your employees.

GARMENT GUARANTEE

At INBLUE, we make it easy to design your own customised uniforms using our services. Whether you are looking to create unique shirts, t-shirts, hoodies, or business suits for your business or high visibility coveralls, jackets or pants for your company, we’ve got you covered. Our design consultants understand your brand image and accordingly suggest designs, styles and colours best suited for your employees.